Is lower internal resistance more critical than higher energy density? In the Li-Po vs. ENEPAQ Li-Ion Battery Modules Comparison Report, we explore the differences between power-oriented and energy-oriented cells to help you understand which better suit your needs.

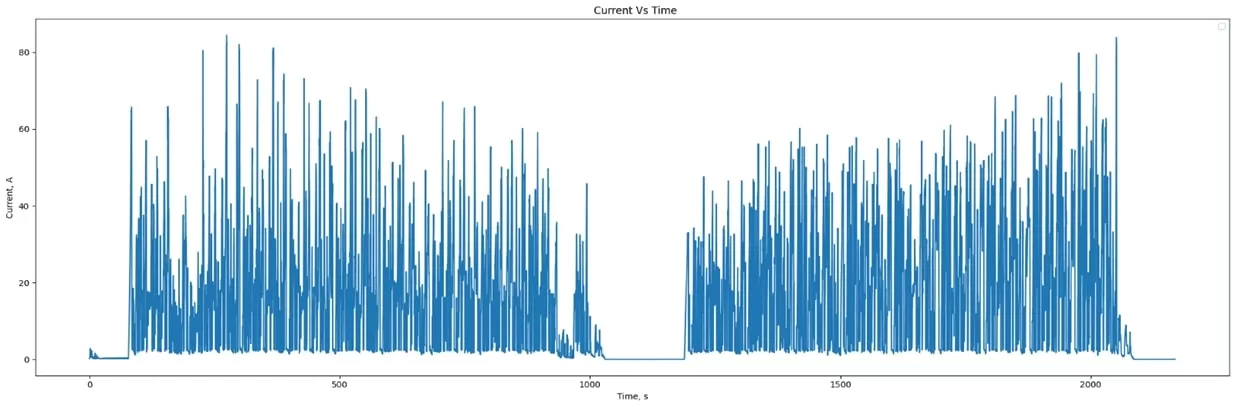

Developers of high-performance applications, including e-formula teams, face various challenges when choosing battery technology. Some teams prefer Li-Po over Li-Ion cells, and others go with more energy-dense Li-Ion options. Interestingly, ENEPAQ recently received a battery log from one e-formula student team, which was taken during endurance race on a racing track. This gave us an opportunity to investigate actual racing conditions and analyze these two options.

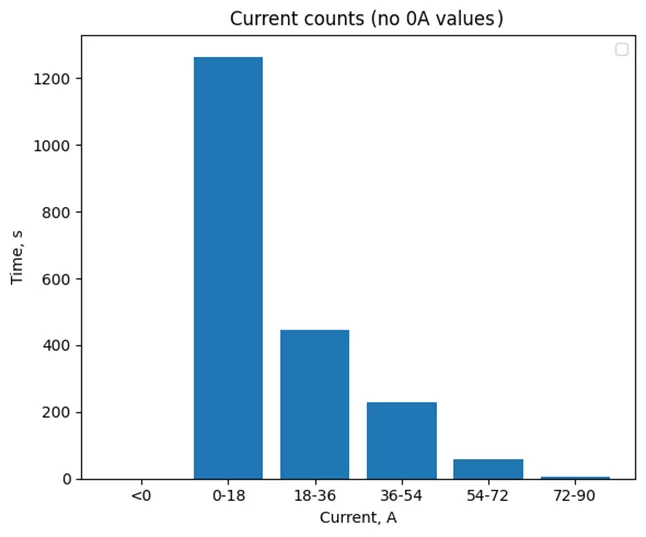

The team have indicated that they did their research on comparing multiple cell options. Among the top candidates, there was ENEPAQ Li1x5pVTC6 module, containing five 18650 Sony VTC6 cells, and an unnamed/redacted LiPo pouch cell of similar capacity. Main difference between these two is that pouch cell has lower internal resistance, while ENEPAQ’s module offers higher capacity per weight. According to the data report, due to higher overall internal resistance and resulting voltage drop, Li-Po may look like a better candidate. However, after analyzing battery discharge current provided by the team, as depicted on graph 1, several things were noted.