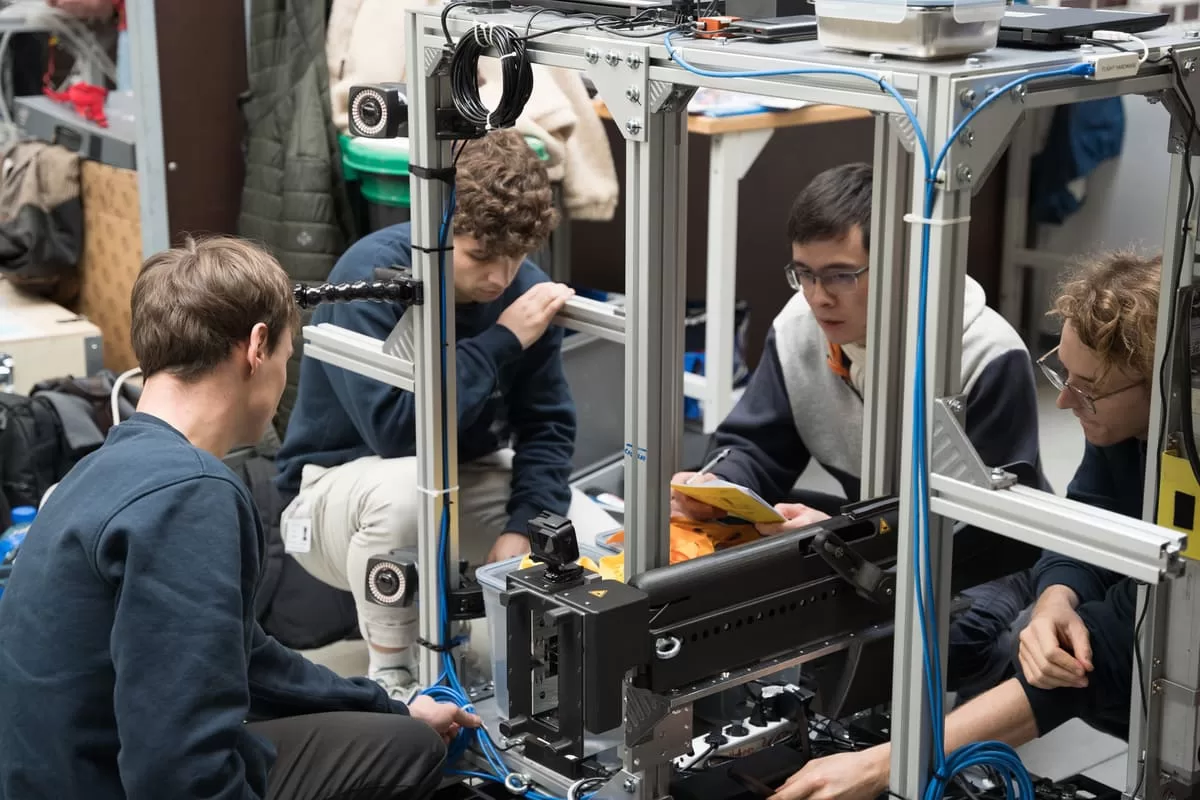

Engineering is all about passion for the unknown, patience and a persistence to dive deeper and turn smart ideas into working prototypes. But the path to success might be bumpy. It is rarely straightforward. ETH Zürich students project – SpaceHopper – is a story with happy ending, but as team member Jorit Geurts laughs, you need to “get your hands dirty”. You need to go through so called “integration hell” to achieve something unforgettable for the rest of your life.

When ENEPAQ received the inquiry for the tiny BMS (Battery Managment System) in this project, we had the feeling that it might be something interesting and unusual. Where it would lead us – nobody knew.

J.Geurts told ETH students’ team story, how everything happened in detail. We talked about what technologies they have used, what challenges faced and how they managed to overcome them. And of course – for the ending – what future their created space robot might expect.

– Let’s start from the beginning. How the project SpaceHopper was born? When and who had this idea to create a robot for moons and asteroids exploration? – ENEPAQ asked J.Geurts.

– SpaceHopper originated as a Focusproject at ETH Zürich back in 2021. A Focusproject is a student led project during which students can chose as part of their bachelor’s degree. During a Focusproject students learn to apply their theoretical knowledge in a practical application/project. The idea for SpaceHopper was born in the Robotics Systems Lab (RSL) at ETH. The goal was set to design a legged robot that could explore celestial bodies such as moons and asteroids.

– Please introduce your team. You are 12 students from ETH Zürich – 11 men and 1 woman. What backgrounds did you come from?

– The current SpaceHopper team consists of ETH 12 students – Fabio, Valerio, Moriz, Jorit, Alex, Max, Jasper, Lukas, Jonas, Andrea, Noah and Lara. Seven of them are from robotics field, three – from mechanical engineering and two – electrical engineering.

Not mentioned on the website (SpaceHopper – Legged Locomotion for low-gravity Environments ETHZ) is Philip Arm. He was our PhD supervisor and helped us in various situations. He was handling all the legal and financial aspects from the ETH side.

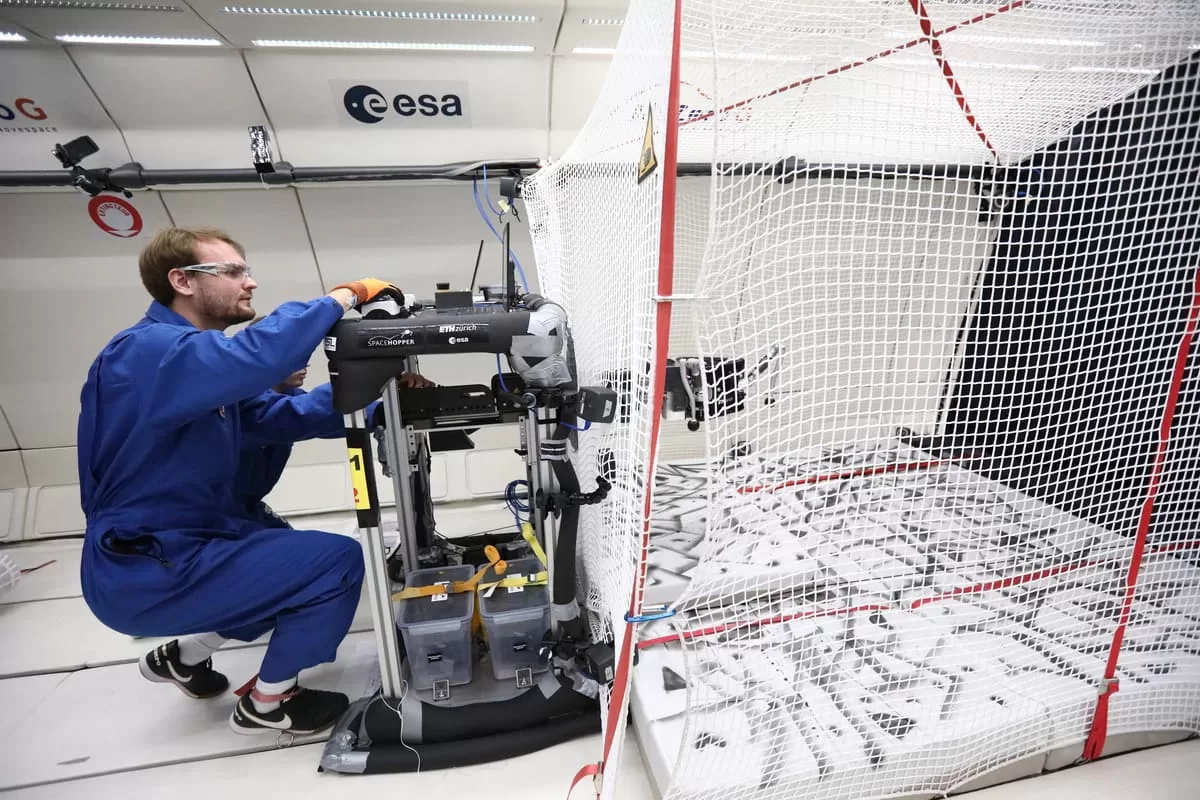

The team started off with the core-team (Alex, Fabio, Moriz, Valerio and Me) who were also part of the Focusproject. We recruited the other students during lectures or by directly contacting them. This way we recruited a very talented and motivated team. They were a huge asset in the preparation for the zero-g flight.

I just want to mention that the Team of the Focusproject is mentioned on our Website SpaceHopper – Legged Locomotion for low-gravity Environments ETHZ under the Focusproject tab. They built the first version of the Robot that we modified for the zero-g flight.

Development of the robot took 2,5 years

– The project you and your team are working on is exceptional and worth story telling. How would you describe the focus and value of it?

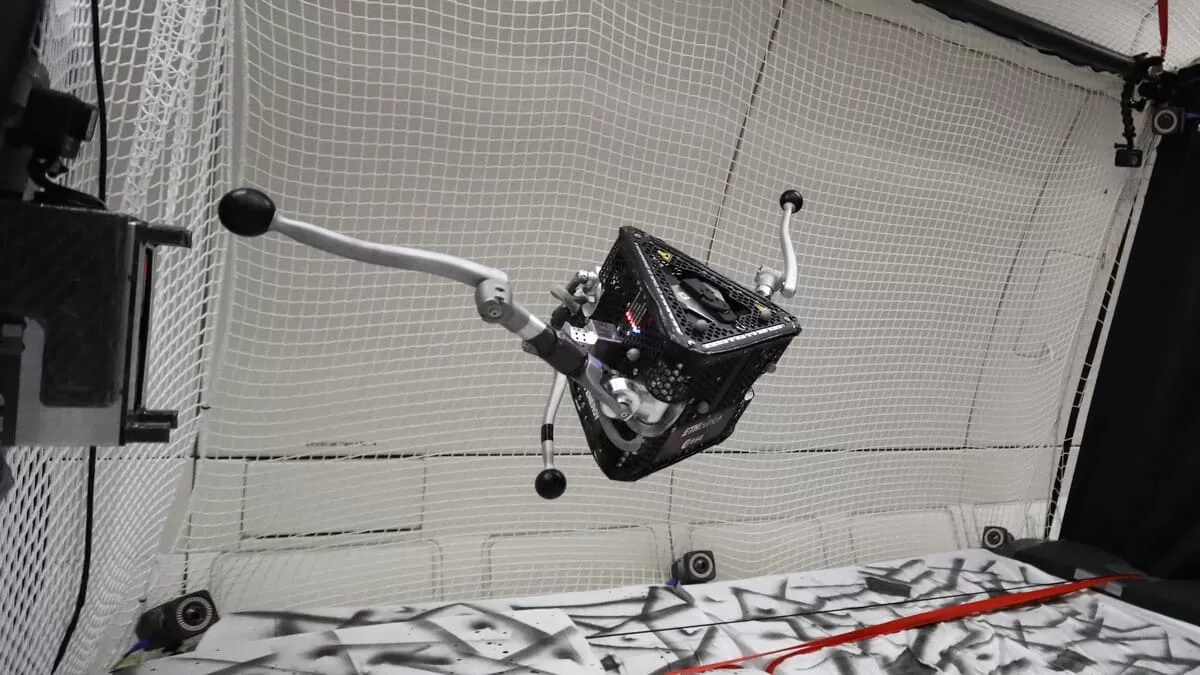

– The focus of the project is to develop legged robots capable of traversing low gravity environments. While this is itself not a new idea, SpaceHopper’s value is the fact that its legs have 3 degrees of freedom each. The robot is controlled using a neural network trained by reinforcement learning.

Recent studies are also looking into this concept, but the greatest value of our project is the fact that we built a system capable of doing this task and successfully testing in a zero-g environment. This is a huge step towards legged robots in low gravity environments. It allows us to gain valuable insight into the ability of a robot to perform attitude control using its legs.

As a student taking part in the project, it was also a huge learning value for me. One can learn all the theoretical aspects of a field/subject. Implementing the theory on a physical system brings so many challenges and new learnings. They are an invaluable experience to take away from the project.

– Let’s talk more about the key features of SpaceHopper. What is it capable of? How much weights? How high can jump? How much cost to make?

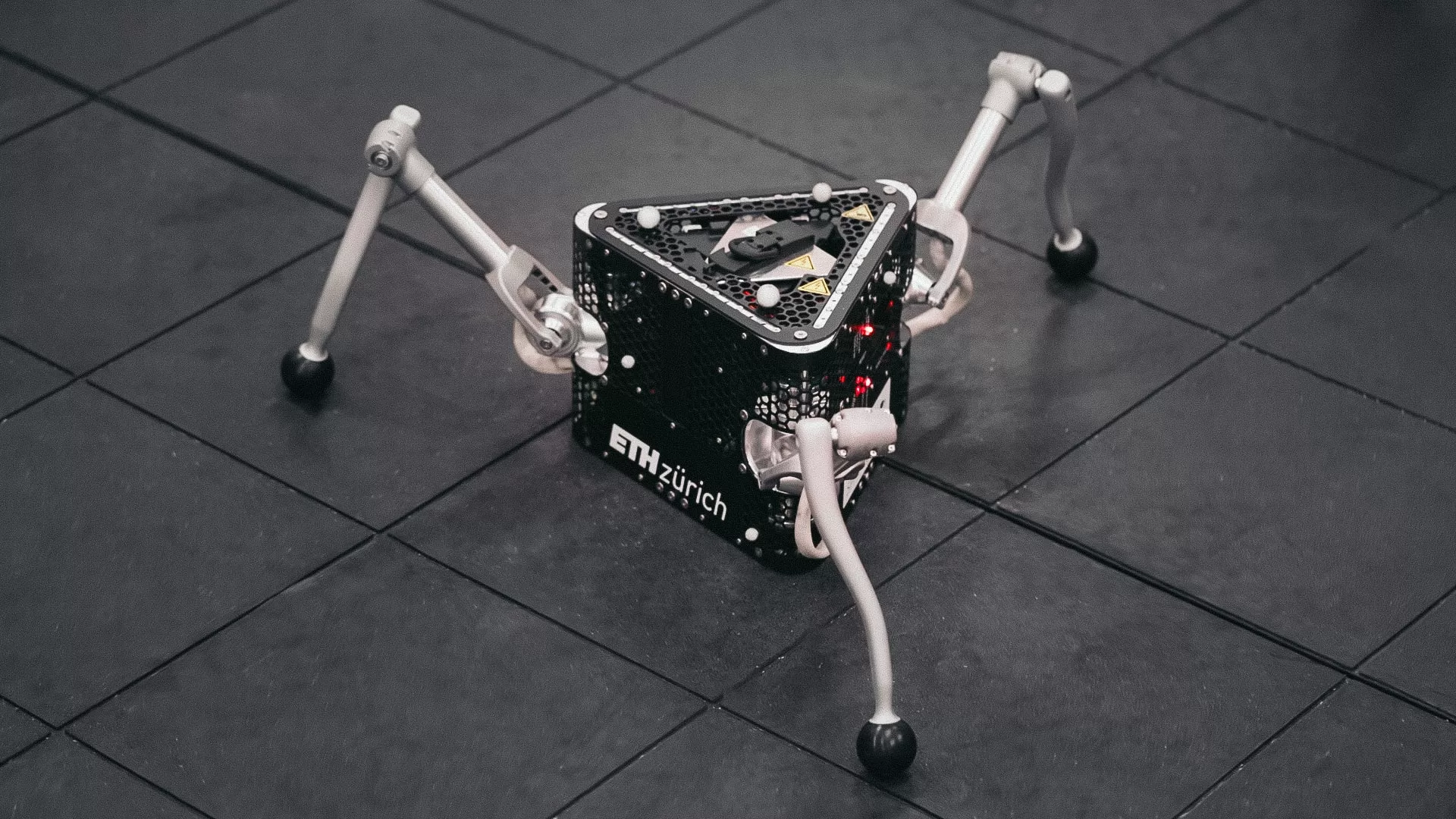

– The body is of triangular shape and has three legs with 3 degrees of freedom each that can be actuated by electrical motors. The body was chosen to be triangular as this is the optimal trade of between complexity and weight (two legs are difficult as standing alone needs an active control system, while four legs have one redundant leg for standing still). The robot gained some weight due to the increase safety mechanism for the zero-g and thus weights around 7 kg (the original robot was 5.2 kg). Depending on the gravity levels the robot can jump various heights. In a simulation we set the gravity levels to the asteroid Ceres, where the gravity is 0.27 m/s^2, and the robot was able to jump to a height of 2.25m and a distance of 6 meters.