For the URVoltage Racing team from Tarragona, Catalunya, learning through hands-on innovation was the driving force behind their journey. Their ambitious goal was to design and build a fully electric motorcycle from scratch and compete in the international MotoStudent competition. In 2025, they took their electric motorcycle project to the next level by choosing the ENEPAQ modular system — enabling them to develop a more advanced, efficient, and compact battery pack to power their race bike.

URVoltage Racing builds electric motorcycle with ENEPAQ modules

Short history of the team

URVoltage Racing was established at the end of 2017, initiated by Víctor Barcelón Llovera. He was then a student of the double degree in Electrical and Electronic Engineering at Universitat Rovira i Virgili (URV). He was the one who proposed the creation of the team to both his fellow students and the professors who would later become their academic advisors.

The idea emerged with the aim of participating in the international MotoStudent competition. It focuses on the design and manufacture of electric and combustion motorcycles by university students. The team participates in the electric motorcycles category.

In its first participation, corresponding to the fifth edition of MotoStudent (2017–2018), URVoltage Racing was made up mostly of students from the degrees in Electronic Engineering, Electrical Engineering, Mechanical Engineering, and the double degree in Electrical and Electronic Engineering at URV.

URVoltage Racing is currently in its fourth consecutive participation in the MotoStudent competition. In each edition, the team is almost entirely renewed, and a completely new electric motorcycle is designed in accordance with the technical regulations set by the competition. Every edition begins from scratch, as the educational aspect of the project is very important.

„For the first time, the team has chosen to use ENEPAQ modules, significantly improving energy efficiency, safety, and structural design compared to previous editions“. L.G.Pesquer

Fourth edition – the most advanced

As professor, who has been involved from the very first edition up to the most recent one, Luis Guasch Pesquer, recalls, at the beginning, the team faced many logistical and financial challenges: there was no proper workspace, financial support was limited, and much of the necessary material was obtained at the last minute.

„Over time, conditions improved considerably. Currently, URVoltage Racing has its own workshop with better infrastructure and more recognition both within and outside the university. This fourth edition of building electric motorcycle is by far the most advanced, as we’ve learned and built upon all the previous experiences “, – summarizes L.G.Pesquer.

In this edition, URVoltage Racing’s primary goal remains the full design and construction of an electric motorcycle developed from scratch, following MotoStudent’s technical and regulatory specifications, which are renewed each edition. The challenge is not only to build a competitive vehicle but also to adapt to new regulations that demand high levels of innovation, safety, efficiency, and sustainability. The team aims to successfully complete the manufacturing process and achieve measurable improvement over previous editions.

The process of building an electric motorcycle

According to L.G.Pesquer, the construction of electric motorcycle follows a structured process.

„First, we analyze the competition’s rules and carry out an initial planning phase, defining goals and deadlines while anticipating potential challenges.

The second step is prototype design. All parts are designed; custom parts are manufactured in-house, and commercial parts are sourced from suppliers. Then, we move to the structural assembly phase, where parts are installed on custom assembly platforms, structures are welded, and the full assembly begins—forming the motorcycle’s core.

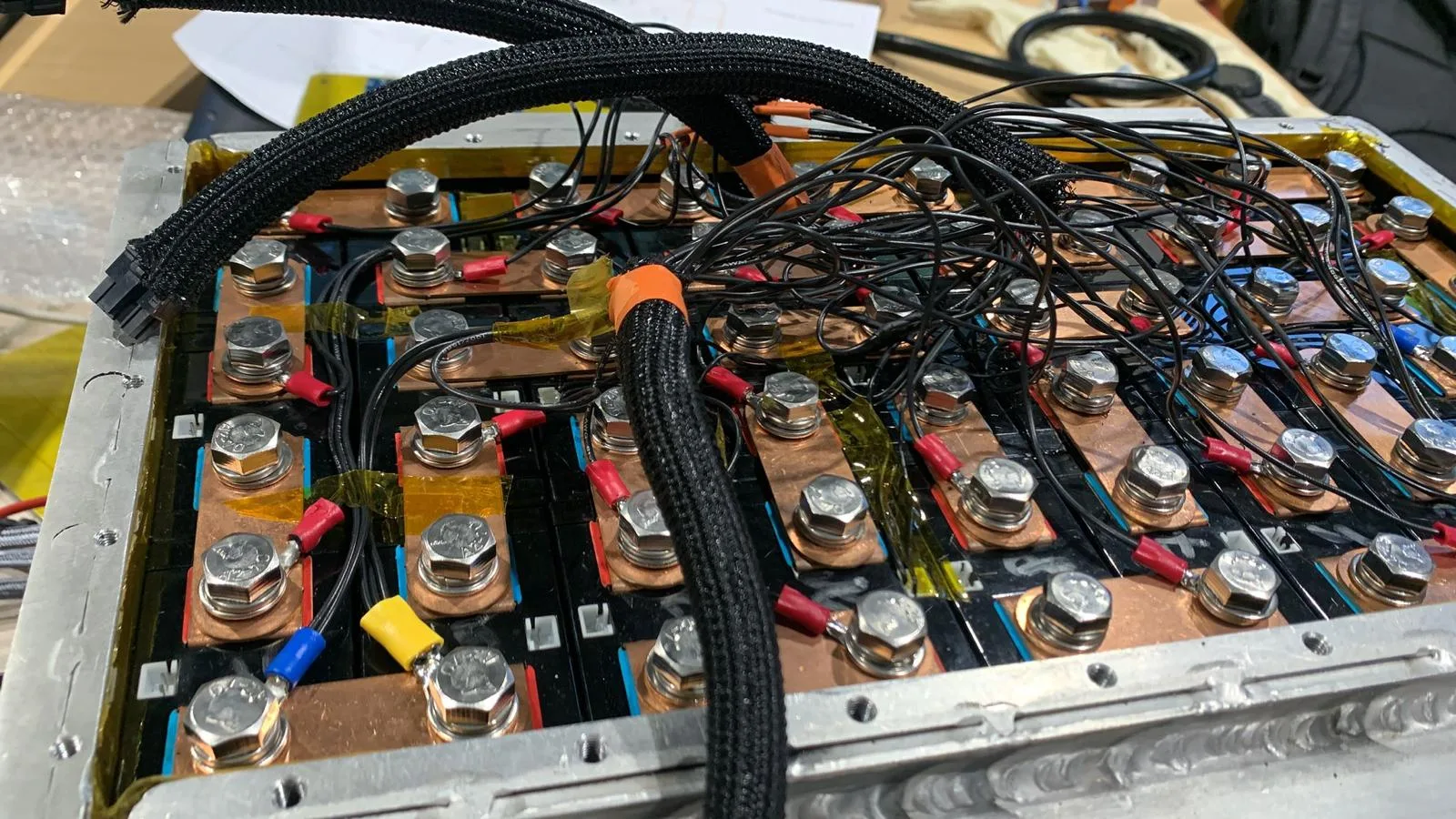

Once the base is ready, the electronic system is integrated. This involves pre-tests and bench trials of control electronics before installing them on the chassis. The HV battery is also designed and assembled, calculating capacity, optimizing cell distribution, and building the battery using ENEPAQ modules for safety and easier assembly. The whole pack is housed in a custom-designed case.

Lastly, the software is developed in five phases: functional requirements gathering, analysis (diagrams, documentation), design (detailed technical specs), programming (Python and Bash), and verification to ensure all functions meet the initial requirements.

This complete process results in a functional, competitive prototype tailored to each edition’s technical demands, ensuring constant progress“, – explains professor Luis Guasch Pesquer, who has been involved from the very first edition up until the most recent one.

„One of the most special moments is the first movement test of the prototype. It’s the first time the team sees months of technical, organizational, and personal work come to life “. Luis Guasch Pesquer.

Most innovative feature – battery pack

URVoltage Racing team admits that one of the most innovative features of this edition is the battery pack.

„For the first time, the team has chosen to use ENEPAQ modules, significantly improving energy efficiency, safety, and structural design compared to previous editions.

The new battery has several advantages. Its optimal design achieves the capacity needed without adding unnecessary weight, enhancing performance. The modular ENEPAQ system is also flexible, safe, and easy to use, simplifying assembly and maintenance while increasing reliability.

This choice was made with safety, versatility, and assembly ease in mind, also optimizing available space within the custom housing. The ENEPAQ system marks a qualitative leap from previous batteries.

In short, the inclusion of ENEPAQ demonstrates the team’s commitment to technological advancement and continuous improvement “, – summarizes Luis Guasch Pesquer.

Challenges and most exciting moments

There is no project without difficulties and meaningful moments worth to wait. URVoltage Racing team electric motorcycle project is not an exception. In team ‘s words – the most challenging part arrives at the end of each month, when several administrative tasks, financial matters, document processing, and material arrivals accumulate.

„This workload often overlaps with key production phases, making inter-departmental coordination essential to stay on schedule. Logistics related to purchases and deliveries can also disrupt timelines. And since we’re students, we must also balance our academic responsibilities, especially during exam periods”, – explains Luis Guasch Pesquer.

But without a doubt special moments also happen during such project as this one.

„One of the most special moments is the first movement test of the prototype. It’s the first time the team sees months of technical, organizational, and personal work come to life. Also, participating in the final race is a thrilling and meaningful experience, combining the adrenaline of competition with the satisfaction of reaching the finish line “, – says the professor.

In his words, team ‘s main strengths lie in the management department, which has been crucial in achieving financial stability, meeting deadlines, and efficiently handling resources. Teamwork also stands out thanks to a clear internal structure, diverse profiles, and constant communication.

„Our ability to learn and improve is key: each new edition has seen us overcome past challenges and advance significantly in all project areas”, – explains a member of URVoltage Racing team.

More about of URVoltage Racing team can be learnt here.

Let’s Build Your Perfect Battery Solution

Unsure which system suits your project? Our experts are ready to guide you in finding for best solution.