At ENEPAQ, we believe in celebrating the creativity and determination of engineers who push boundaries. That’s why we’re sharing real-world case studies — to highlight how our TinyBMS battery management system helps bring bold ideas to life across a wide range of projects.

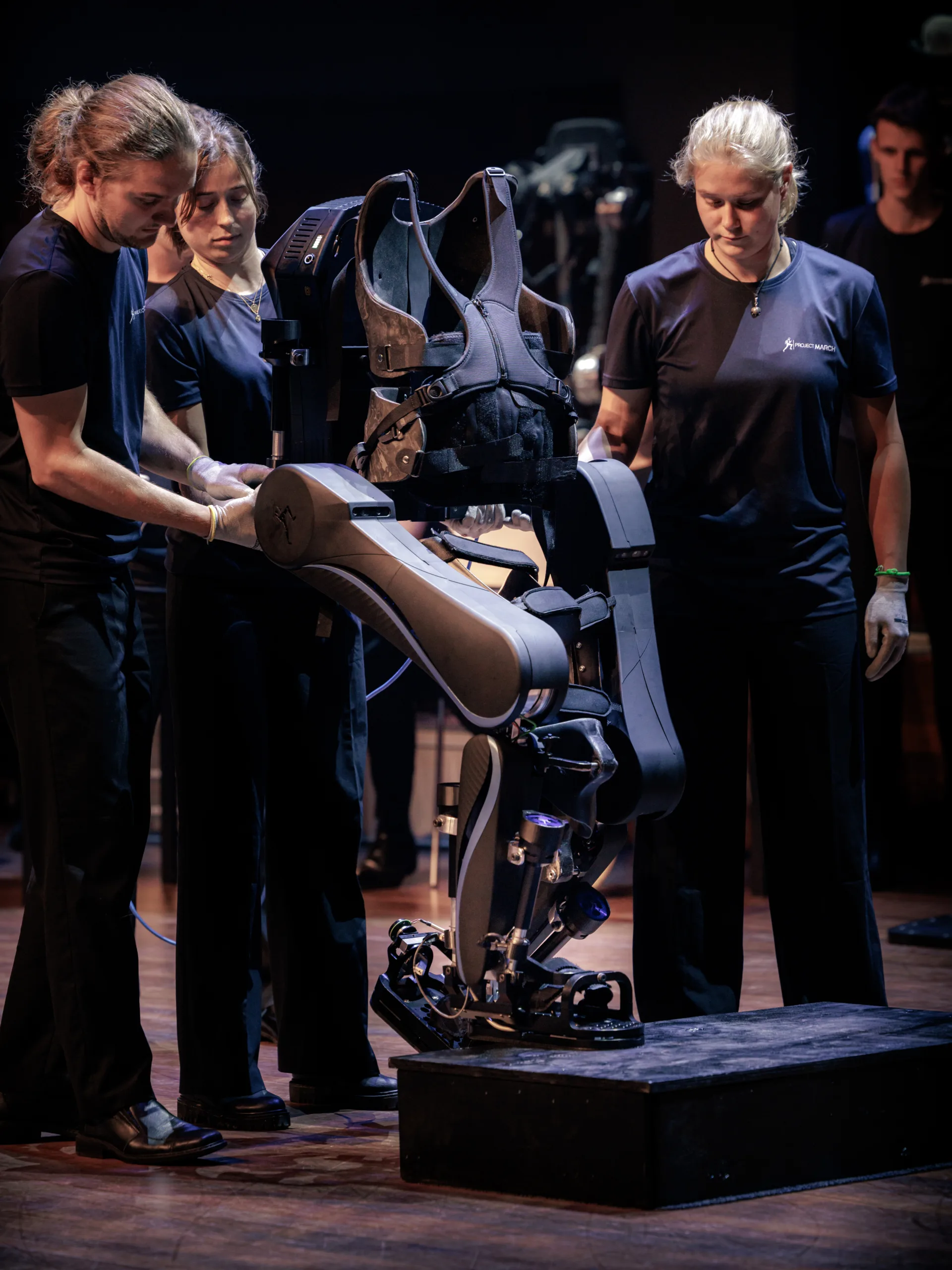

One inspiring example comes from Project MARCH, a dedicated student team from TU Delft, known for building next-generation exoskeletons. In their 10th exoskeleton prototype, nearly a decade of innovation led to a major breakthrough: the device could stand upright, fully self-balanced, for over an hour — powered by a battery pack small enough to fit in the palm of your hand. At the heart of that power system – ENEPAQ’s TinyBMS.