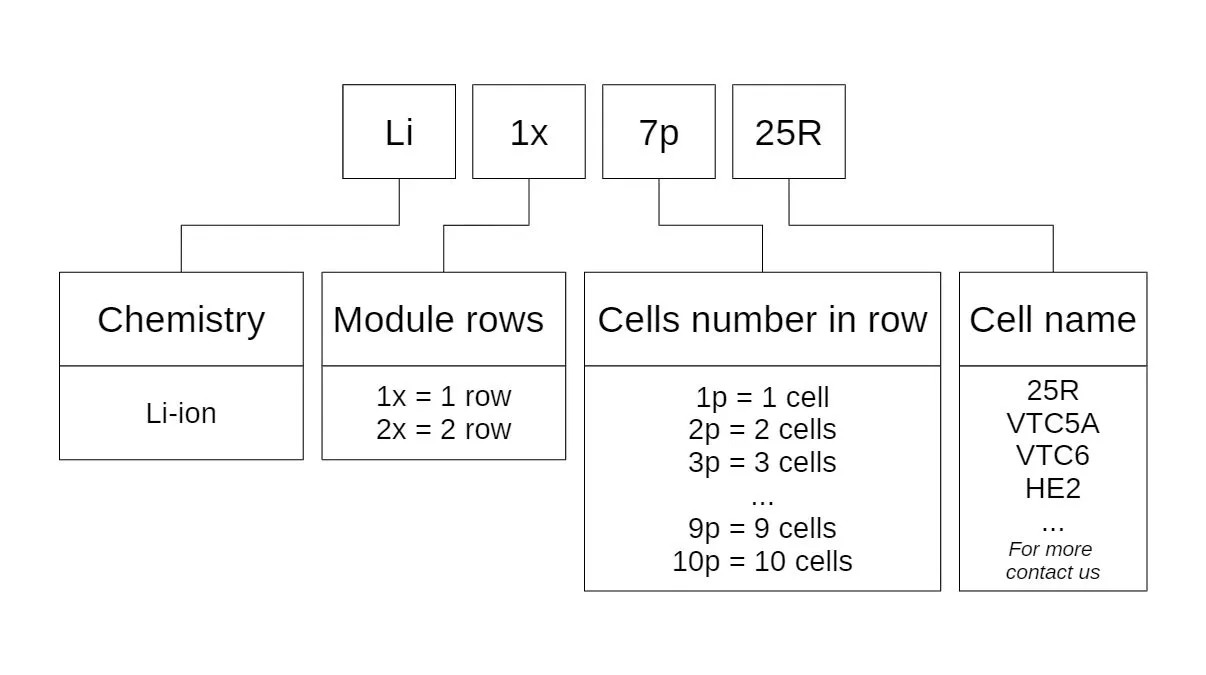

Samsung 25R 18650 Li-ion Battery Module

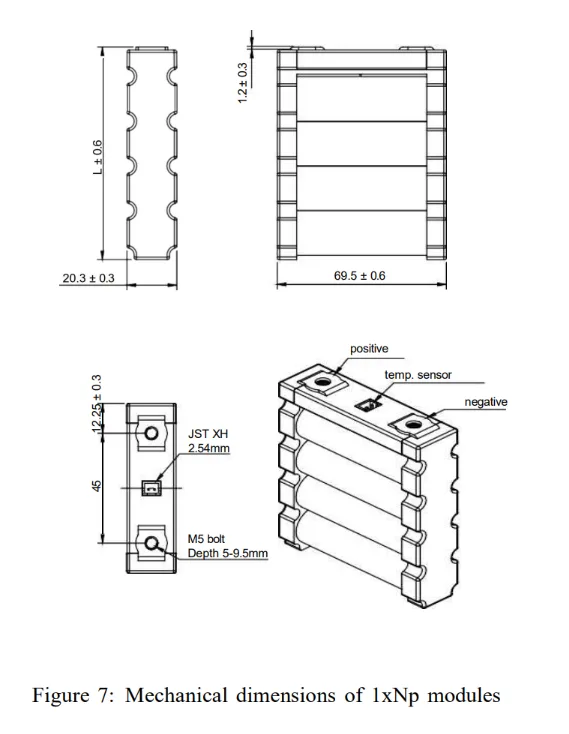

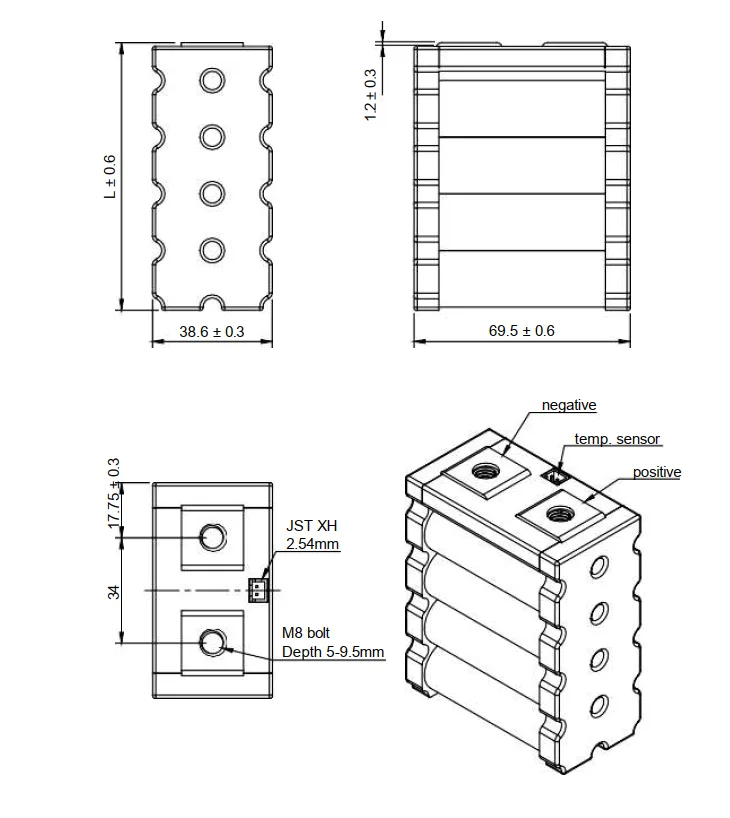

Battery module from 1s1p to 1s20p with 18650 size cells.

Key Features:

- UN38.3 certified

- Small size: 197-343 Wh per liter

- Low weight: 161-168Wh per kg

- Individually fuse-protected cells

- Ultra-low and equal self-discharge

- Convenient thermal control

- Built-in temperature sensors

- UL94-V0 rated, fire-retardant plastics

Looking to buy locally?

Check out our network of distributors.

SAMSUNG 25R LI-ION BATTERY MODULE

Enepaq’s innovative Samsung 25R Li-ion Battery Modules, built with high-performance Samsung 25R Li-ion Battery cells, offer the perfect combination of lightweight design, high power output, exceptional quality, built-in safety features, and ease of use.

Enepaq Battery Modules blend the latest battery technology with safety and ease of use. Each module contains several 3.6V 18650 Li-ion cells connected in parallel. Multiple blocks can be connected in parallel and series to form high voltage Battery Packs of various shapes and sizes.

ENEPAQ SAMSUNG 25R LI-ION BATTERY MODULES: ENGINEERED FOR EFFICIENCY

While cylindrical cells offer superior quality and safety, Enepaq recognizes the challenges they pose for large battery pack assembly. That’s why Enepaq battery modules are specifically designed to address these issues:

- Modular Design: Enepaq modules integrate cylindrical cells within a pre-engineered format, eliminating the need for custom trays and simplifying battery pack design.

- Simplified Connections: Enepaq modules are specifically designed for easy connections. No engineering expertise is required! Simply assemble them using busbars and bolt kits – no welding or additional wiring necessary.

- Scalable and Efficient Assembly: Enepaq modules allow for faster and more efficient assembly of large battery packs due to their pre-configured format and simplified connections.

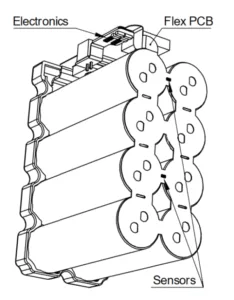

- Specific design based on air cooling: Enepaq battery modules utilize strategically placed air gaps within the housing to facilitate superior thermal management. This innovative design leverages air circulation to effectively dissipate heat generated by the battery cells, maintaining optimal operating temperatures for the entire pack.

- Integrated temperature sensors: Enepaq modules are with JST 2 pin-XH connection on each module (you can connect the modules with the custom-made device, that can read module temp data and provide it to your BMS unit)

- Fuse Control: Protects cells from overload and potential fire.

By incorporating high-quality cylindrical cells within a well-designed module, Enepaq offers a solution that leverages the benefits of cylindrical cells while mitigating the challenges associated with their integration.

KEY FEATURES OF SAMSUNG 25R LI-ION BATTERY MODULES

CUSTOMIZATION OPTIONS

ADVANCED TEMPERATURE MONITORING SYSTEM

APPLICATIONS